CUT+COOL Eco drilling and cutting oil

Drilling/cutting oil CUT+COOL Eco

CUTOIL-DRILL-(CUT-COOL)-ECO-400ML

Register now and access more than 125,000 products

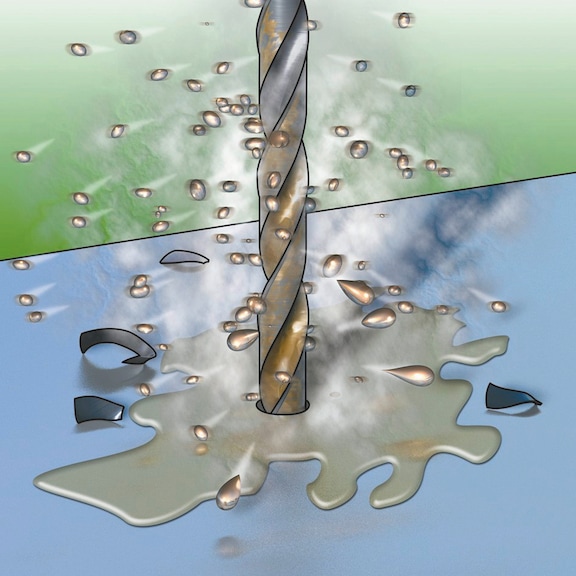

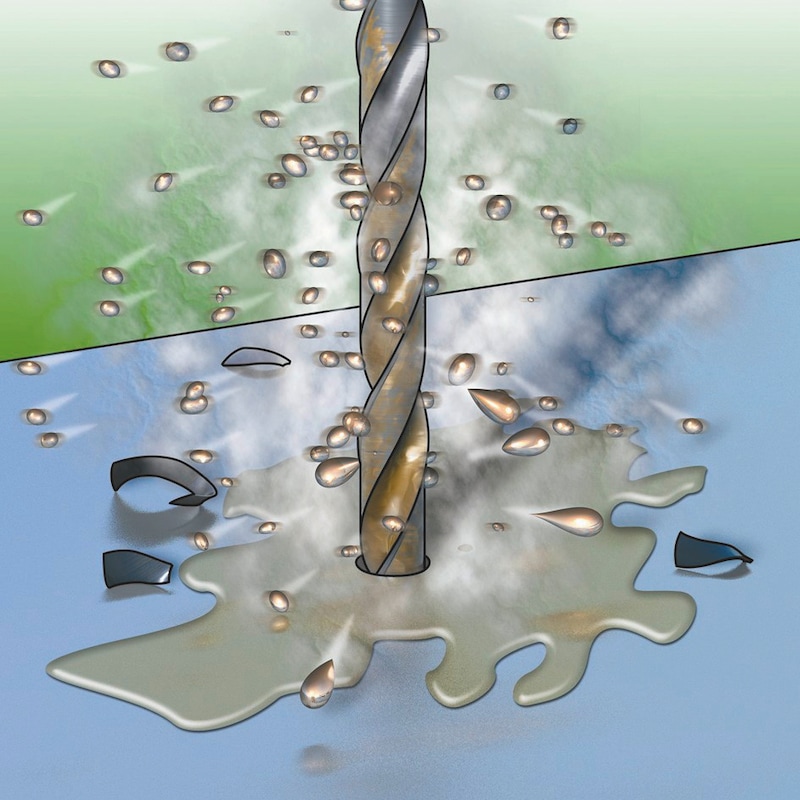

Aerosol can with ECO-Stop technology

- Up to 2500 applications possible due to predefined quantity per valve operation

- Minimal smoking

Easy to use

No cleaning of metals prior to installation or further treatment (e.g. welding) required with low usage concentrations

Neutral behaviour

- Contact with sensitive materials (e.g. marble, plastic and electrical components) possible

- Odourless

Oil-soaked cleaning cloths should only be stored in non-flammable, self-sealing, tightly sealed, and appropriately labelled containers (BGI 560).

| Drilling and cutting oil | Drilling and cutting oil Perfect | Drilling and cutting paste Perfect | Drilling and cutting oil Eco | Drilling and cutting foam | Cutting oil DVGW | Coolant Ultra | Coolant Ultra HD | |

| Materials | ||||||||

| Machining processes | ||||||||

| Features | ||||||||

| Base material | Mineral oil | Mineral oil with synth. Ester | Mineral oil with synth. Ester | Synth. Ester | Glycol and ester | Ester | Mineral oil | Mineral oil |

| Steel, alloyed steel | xx | xxx | xxx | xxx | xxx | xx | xx | xxx |

| High-alloy steel | xx | xxx | xxx | xxx | xxx | xx | xx | xxx |

| Cast iron, grey cast iron | xx | xxx | xxx | xx | xxx | x | xx | xxx |

| Carbide | xx | xxx | xxx | xx | xxx | x | x | xx |

| Non-ferrous base metal (copper, brass etc.) | xx | xxx | xx | xxx | xxx | x | x | xx |

| Titanium | x | xxx | xxx | xx | xxx | x | x | xx |

| Magnesium | x | xxx | xxx | xx | xxx | x | x | xx |

| Aluminium, aluminium alloys | x | xxx | xxx | xx | xxx | x | xx | xxx |

| Turning, turning machines | xx | xxx | x | x | x | x | xx | xxx |

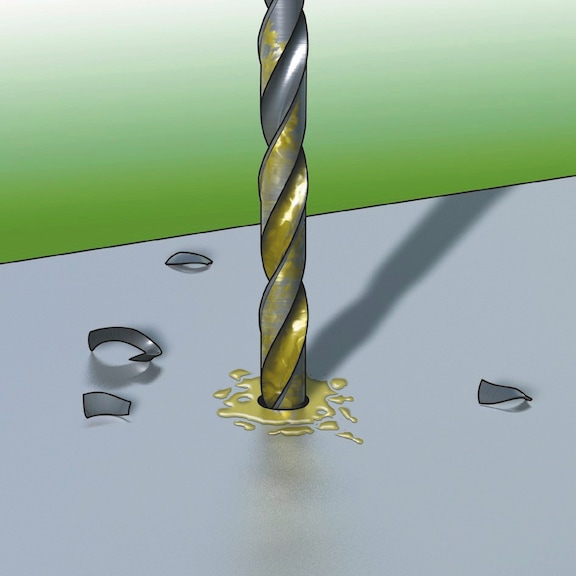

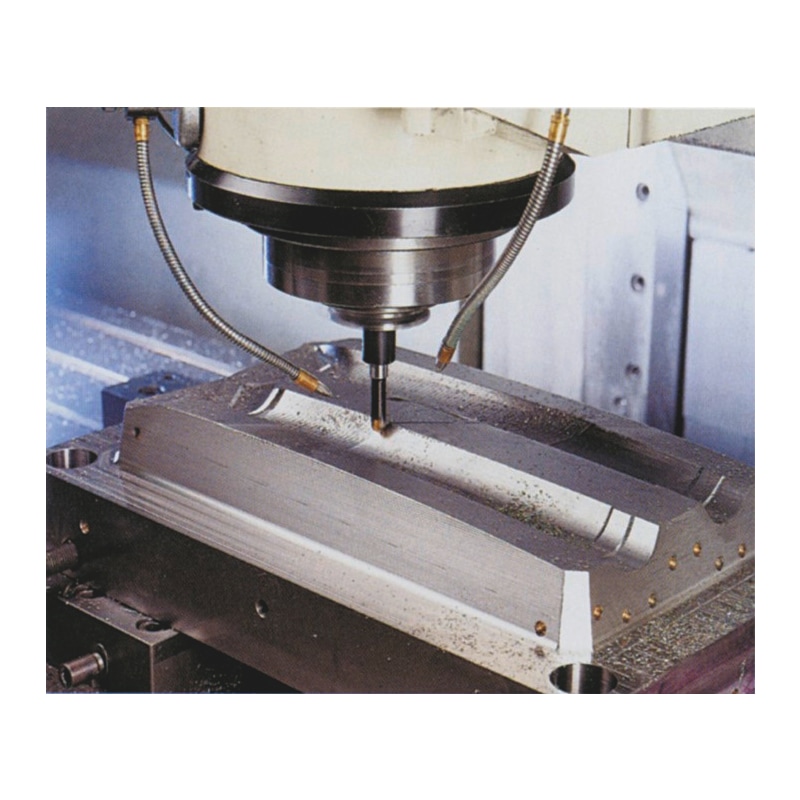

| Drilling, countersinking, reaming | xx | xxx | xxx | xxx | xxx | x | xx | xx |

| Deep drilling | x | xxx | xxx | xx | xx | x | x | xx |

| Sawing | xx | xxx | xx | xxx | xxx | x | xx | xx |

| Thread cutting | xx | xxx | xxx | xxx | xxx | xx | xx | xx |

| Thread moulding, rolling | xx | xxx | xxx | xxx | xxx | x | x | xx |

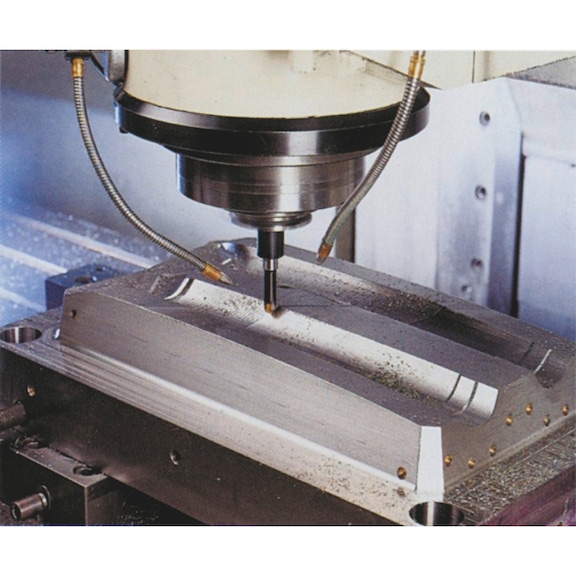

| Milling | x | xxx | x | xx | xx | x | xxx | |

| Sanding | x | xxx | x | x | x | x | xxx | xx |

| Forming, rolling, bending | x | xxx | xx | xx | xx | x | x | xx |

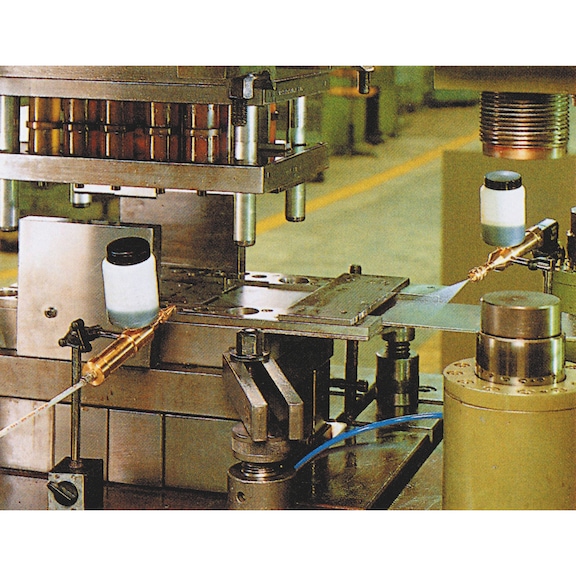

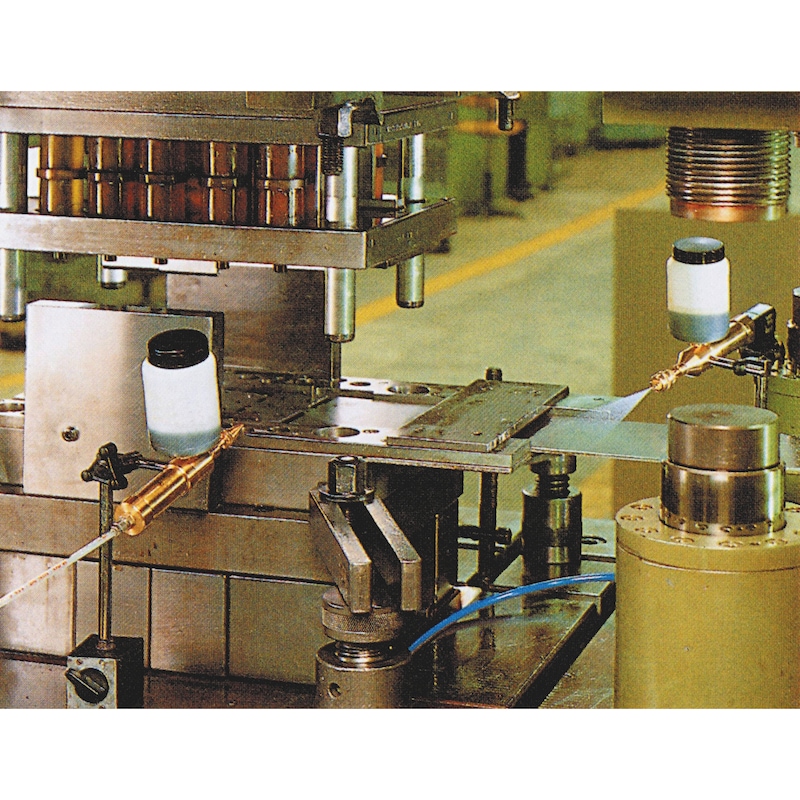

| Punching, fine punching | x | xx | xx | xx | x | x | x | |

| Broaching, toothing | x | xxx | xx | xxx | xxx | x | x | x |

| Viscosity (mm²/s) | 12 | 25 | Paste-like | 35 | n/a | 5 | 66 | 76 |

| Minimum quantity lubrication | ⎷ | ⎷ | ||||||

| Free from mandatory warning symbols | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Can be used upside down | ⎷ | ⎷ | ||||||

| DVGW-approved | ⎷ | |||||||

| Biodegradable/approved for use with food | ⎷ | |||||||

| Extremely high lubricating performance | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | |||

| Extremely long tool life | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ||

| Minimal smoke formation | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ||

| Extremely low consumption | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Good creeping properties | ⎷ | |||||||

| Free of boric acid | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Low-foaming | ⎷ | ⎷ | ||||||

| Extremely high microbial stability | ⎷ | ⎷ | ||||||

| Water hazard class | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 |

| Formaldehyde-free | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Extremely gentle on the skin (amine-free) | ⎷ | ⎷ | ⎷ | |||||

| xxx excellent suitability xx good suitability x less favourable suitability ⎷ applicable | ||||||||

The usage instructions are recommendations based on the tests we have conducted and are based on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

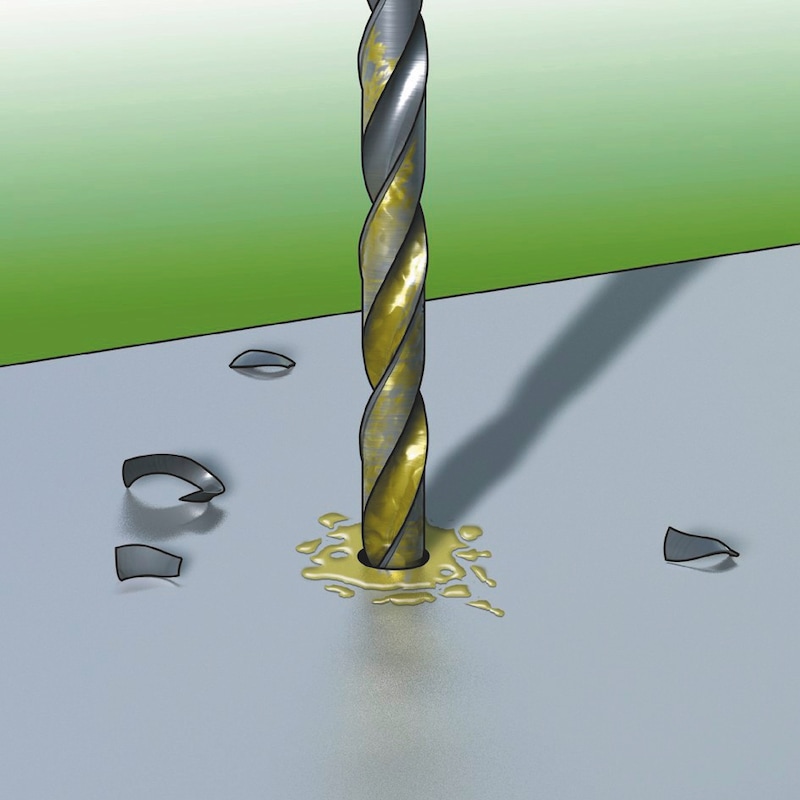

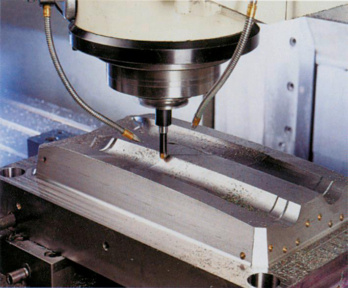

For use on-site, with loss lubrication and in food-contact areas. Ideally suited for use with surface pressures between the workpiece and tool and for all complex machining operations. Can be used for shaping steel, aluminium and non-ferrous heavy metals.

No cleaning of metals before assembly or further treatment (e.g. welding) is required for low application concentrations. The product is processed as delivered.

Contents | 400 ml |

Container | Aerosol can |

Colour | Light yellow |

Smell/fragrance | Neutral |

Chemical basis | Synthetic ester |

Shelf life from production | 12 Month |

Density | 0.77 g/cm³ |

Density conditions | at 20°C |

Acid-free | Yes |

Chlorine-free | Yes |

Free from heavy metals | Yes |

Min. flashing point | 275 °C |

Silicone-free | Yes |

Resin-free | Yes |

Kinematic oil basis viscosity | 35 mm²/s |

Phosphor-free | Yes |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!